The KPT series electric transport trolley is a cable-powered electric flat cart. A support chain is provided on the electric transfer trolley. One end of the cable is connected to the ground power supply. The steel wire rope is pulled into the control box through the cable pulley, and then the YZ motor on the flat trolley is powered. The motor drags the flat car through the reducer to run smoothly. This series of electric transport trolley are suitable for hoisting and metallurgy in harsh industrial and mining conditions. The electric transport cart has a simple and reliable structure, economical price, convenient maintenance, and convenient track construction. It is a set of traditional electric rail flat car selection solutions; suitable for large-tonnage over-span solutions.

The main structures of the KPT series electric transport trolley include frame, motor, reducer, wheel, cable, control box, etc.

Trolley frame:

The frame structure of the trolley is a frame structure welded by four longitudinal beams, several cross beams and a work table cover. The support method adopts an eight-point load-bearing form. This structure is paired with the bearing seat on the wheelset to effectively reduce the table height and improve the frame stress. The work table is equipped with a detachable inspection hole, and four lifting holes or hooks are provided on both sides of the frame for lifting and turning. The longitudinal beam and cross beam of the frame are made of the same I-beam and channel steel combination, and the workbench panel is made of high-quality carbon steel plate. The frame strength is designed to be 1.25 times the rated load, so as to ensure that the load-bearing frame will not deform when subjected to a certain impact.

Electric flatbed car motor:

The motor is a YZ series lifting metallurgical motor with a rated voltage of 380V, a rated frequency of 50HZ, a power of 3.7~7Kw, an insulation grade of F, and a protection grade of IP44. The power of the motor can be selected according to the rated tonnage of the electric flatbed car.

Electric transport trolley reducer:

It adopts the heavy-duty standard of the lifting and transportation industry, and is dedicated to the shaft-holding hard-toothed flat trolley. It has a compact structure, high reliability, good versatility, and is easy to install and maintain. The gears are all made by carburizing, quenching, and grinding, and are produced by a professional gear manufacturer.

Electric transport trolley wheels:

The wheels are special wheels for cranes. The wheels are made of ZG55, which is overall quenched, and the hardness of the wheel tread and the inner side of the wheel rim is HB320-380, with a depth of 20mm. The axle is made of 45 steel and tempered. The bearing seat is made of ZG45, and the bearing is a radial roller bearing. The axial automatic micro-alignment of the bearing can eliminate and overcome the elastic deformation of the flat car under no-load and full-load conditions and the deviation of the horizontal parallelism of the track, ensuring the balance of the flat car running on the track and improving the service life. After the wheel is assembled, it rotates flexibly, and the wheel is a single wheel rim. Considering the wheel pressure of the electric transport trolley, the wheel adopts a heavy-duty wheel specially used for cranes, with 4 wheels and 2 drives.

On-board control box: (If a remote control is installed, the effective distance is 100 meters)

The on-board control box consists of a control box and a control cable. The control box is equipped with forward, reverse and emergency power-off buttons, and the length of the control cable is about 2.5-3m. The on-board control box can be stored in the box on the side of the transport trolley when not in use, and can be taken out for operation when in use.

Sound and light alarm:

To remind other staff to avoid the transport trolley when it is running to ensure safety. Each transport trolley head is equipped with a new type of sound and light warning integrated alarm at both ends.

Electric flatbed car control box:

The load control box is installed on the lower side of the electric transport trolley frame to play a protective role. The electrical components are all made of products with high technological content and good reliability. The control system is equipped with leakage protection switch overload protection and emergency power-off control elements, and the control circuit is set to a safe voltage of 36v. The whole set of electrical equipment has power distribution protection, short circuit protection, overcurrent protection, pressure loss protection, zero position protection, emergency power-off protection, safety signs, etc., which ensures that the transmission performance, control performance, and protection performance are safe, accurate and reliable, and can be safely parked in an emergency. Therefore, it is safer and more reliable to use our company's products.

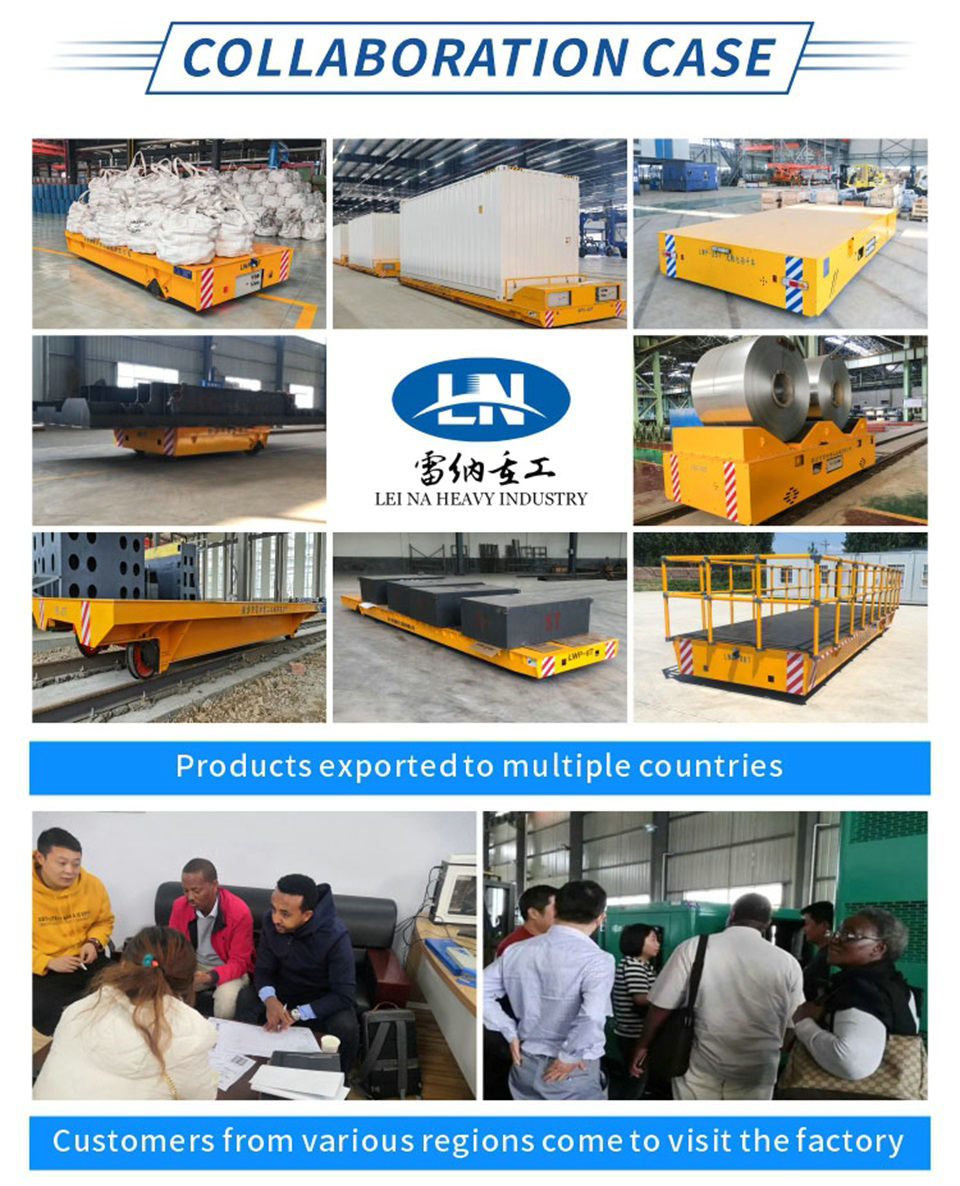

WHAT LEINA CAN OFFER