Product Overview

Industrial electric rail transfer vehicles are electrically powered material handling equipment that travels on pre-laid steel rails. With its stable and reliable operation and strong load-carrying capacity, they meet the needs of efficient transfer of heavy materials, large workpieces, molds, and complete sets of equipment within factories. They are widely used in industries such as metallurgy, machinery manufacturing, automotive, shipbuilding, mold manufacturing, warehousing, and production lines.

Power Supply Methods

Depending on the application scenario, common power supply options for industrial electric rail transfer vehicles include:

Battery Power (KPX Series)

Onboard battery power eliminates cable constraints and provides flexible operation.

Suitable for medium- and long-distance transport with flexible space requirements.

Low-Voltage Rail Power Supply (KPD Series)

Power is transmitted directly through the rails, allowing the vehicle to draw power while in motion.

Suitable for long-duration, high-tonnage, and high-frequency continuous operation.

Cable Reel/Tow Cable Power Supply (KPC Series)

Powered by cables, it offers stable power and a simple structure.

Suitable for medium- and short-distance transport and fixed working environments.

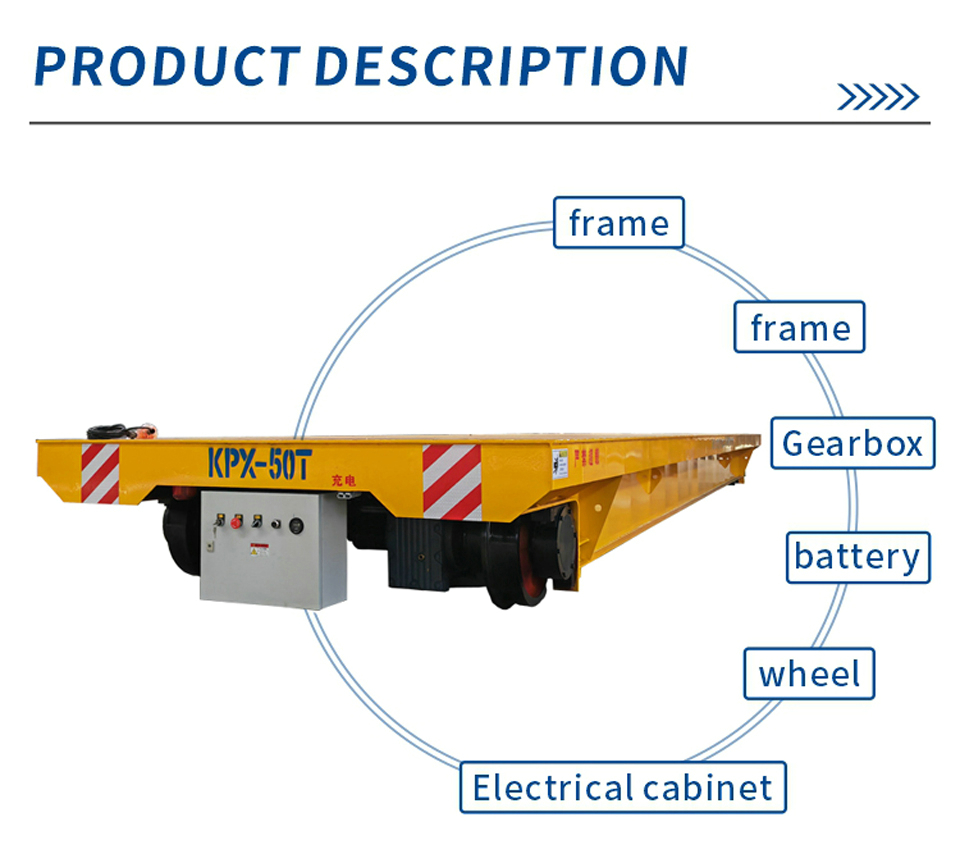

Structural Features

Sturdy Frame: The vehicle body utilizes a box-type welded structure constructed of high-strength steel plates, providing excellent load-bearing performance.

Smooth Drive: Equipped with a reducer and motor combination, it operates smoothly, with no shock during starting and braking.

Safety Design: Equipped with audible and visual alarms, emergency stops, limit switches, and an optional anti-collision sensor system to ensure safe operation.

Flexible Control: Supports both handlebar-controlled and wireless remote control modes, allowing single-person operation.

Functional Expansion: A hydraulic lift, roller conveyor, V-frame, and other devices can be added to meet user needs, enabling a variety of transport functions.

Technical Parameters (Customizable)

Rated Load Capacity: 5 tons – 500 tons

Motor Power: 2 kW – 50 kW (depending on tonnage and operating conditions)

Operating Speed: 0 – 25 m/min (Stepless Speed Adjustment Optional)

Track Gauge: Standard 1435 mm (or customizable to suit the user's factory track)

Operating Distance: 10 m – 200 m (depending on power supply method)

Control Method: Handle / Wireless Remote Control / Automatic Control

Safety Devices: Emergency Stop, Audible and Visual Alarm, Limit Switches, Anti-Collision, Overload Protection

Application Scenarios

Mechanical Manufacturing: Transfer of large machine tool components and semi-finished equipment.

Mold Shop: Handling, Installation, and Commissioning of Molds.

Steel and Metallurgy: Transfer of Steel Coils, Billets, and Steel Structures.

Automotive and Shipbuilding: Transport of Components, Cargo Vehicles, and Shipbuilding Modules.

Warehousing and Logistics: Handling of heavy objects between workshops and warehouses.

Production Lines: Serving as a logistics connection between process links.

Product Advantages

✅ High load capacity – Meets diverse load requirements, from a few tons to hundreds of tons.

✅ Smooth and reliable operation – Utilizes a soft-start system for safe and impact-free transport.

✅ Energy-saving and environmentally friendly – Powered by electricity, it produces zero exhaust emissions and is environmentally friendly.

✅ Easy operation – Dual-mode remote control and handle control simplify manual operation.

✅ Highly customizable – Dimensions, power supply methods, gauges, and additional features can be customized to meet customer needs.