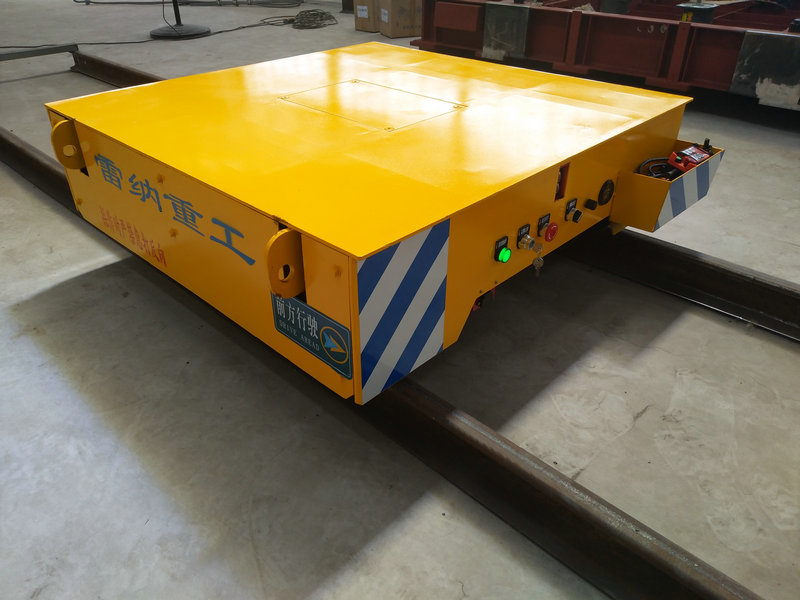

The small-tonnage electric rail transfer vehicle is an intelligent material handling device developed specifically for factory floors, warehouse logistics, and laboratory environments. With a load capacity typically ranging from 1 to 5 tons, it is battery-powered and operates on rails. It features a compact footprint, flexible and efficient operation, and is safe and environmentally friendly.

Whether handling small molds, parts, or packaging pallets, it enables efficient and stable transfer, significantly improving logistics efficiency on the production floor.

Why choose a small-tonnage electric rail transfer vehicle?

A Solver for Manual Labor

Traditional manual push carts are laborious, inefficient, and pose safety risks.

Electric drive allows for easy handling, reducing worker workload and preventing accidents.

An Accelerator for Workshop Logistics

Enables rapid transfers between workstations, shortening production cycle times.

Supports continuous operation, improving overall production line efficiency.

A Balance Between Environmental Protection and Cost Effectiveness

Battery-powered, environmentally friendly, and zero-emission.

Long-term operation is less expensive than manual labor or forklifts.

Product Highlights

✅ Compact Size, High Adaptability - Compact footprint, suitable for narrow workshops and complex workstation layouts

✅ Intelligent Control - Joystick operation + wireless remote control, multi-mode control for greater flexibility

✅ Safety Assurance - Audible and visual alarms, emergency stop switch, and limit switches ensure worry-free transportation

✅ Powerful Power - Stable load capacity even with small tonnage, climbing and turning without loss of stability

✅ Modular Customization - Optional hydraulic lift, roller conveyor, V-bracket, weighing system, etc. can be added to meet different process requirements

Technical Parameters (Reference Configuration)

Rated Load: 1–5 tons

Battery Voltage: 24V / 48V (Lithium/Lead-Acid Available)

Battery Life: 6–8 hours

Charging Time: 4–6 hours

Operating Speed: 0–20 m/min (Stepless Speed Adjustment)

Control Method: Joystick Control / Wireless Remote Control

Track Compatibility: P18–P38 Lightweight Track or Custom Track

Application Scenarios

Mold Shop - Transport of small molds between production lines and workstations

Electronics factories – Turnover handling of precision parts and electronic components

Mechanical manufacturing – Connection to production lines for small-batch parts

Warehousing and logistics – Rapid transfer of pallets and packaging boxes

Laboratories/R&D centers – Safe handling of prototypes and trial products

Customized services

Customized structures: Flatbed, guardrail, roller, lift, etc.

Power options: Lithium battery or lead-acid battery options, with flexible battery life configurations

Control system: Expandable automatic docking and positioning navigation functions

Safety features: Optional infrared sensors, collision avoidance, and intelligent limit switches