KPJ Cable Drum Rail Transfer Cart uses a cable to supply 380V power to the Transfer Cart by retracting and releasing the winding device on the Transfer Cart. The winding device is placed under the track Transfer Cart and directly controls the start, stop, forward, backward, speed regulation, etc. of the motor through the AC control system. The Transfer Cart's operating system uses a low-voltage 36V power supply control; the Transfer Cart table allows the installation of hydraulic or mechanical lifting systems and other devices; and can achieve automated remote control.

KPJ Cable Drum Rail Transfer Cart can be used in harsh environments such as high temperature, low temperature, and explosion-proof.

KPJ Cable Drum Rail Transfer Cart adopts box beam structure, which has strong bearing capacity, no deformation, simple structure, low cost and low requirements for track laying. It is a common rail transfer cart for workshops. Compared with KPX Transfer Cart, it is not limited by the use time. Compared with KPD Transfer Cart, it has low requirements for track laying. KPJ Cable Drum Rail Transfer Cart is suitable for any load and high frequency of use. For running distances exceeding 50 meters, a cable arranging device is needed to lay and wind the wire. The maximum running distance can meet 200 meters.

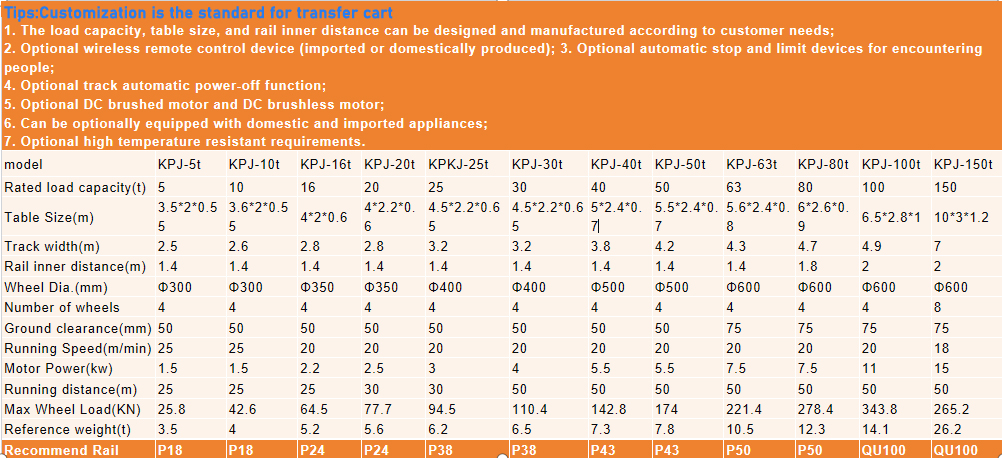

KPJ Cable Drum Rail Transfer Cart Specifications

KPJ Cable Drum Rail Transfer Cart Details

KPJ Cable Drum Rail Transfer Cart Manufacturer

Xinxiang LEINA Heavy Industry Machinery Co., Ltd. specializes in customized production of 1-500 ton KPX transfer carts,LWP electric trackless transfer carts, KPT Towing Cable Transfer Cart,KPJCable Drum transfer trolley,electric lifting transfer carts, rail traction trolley and other handling equipment. All of them have passed ISO, ECPSC, CE authoritative certifications

LEINA has over 23 years of industry experience, leading technology. There are various types of transfer Carts with complete specifications. Factory direct supply prices provide higher cost-effectiveness

Used for spray painting rooms in the oil and gas industry, chemical industry, etc., it can be used in risk environments such as explosion-proof, waterproof, and high temperature resistance.